Can you introduce Mint-Tek?

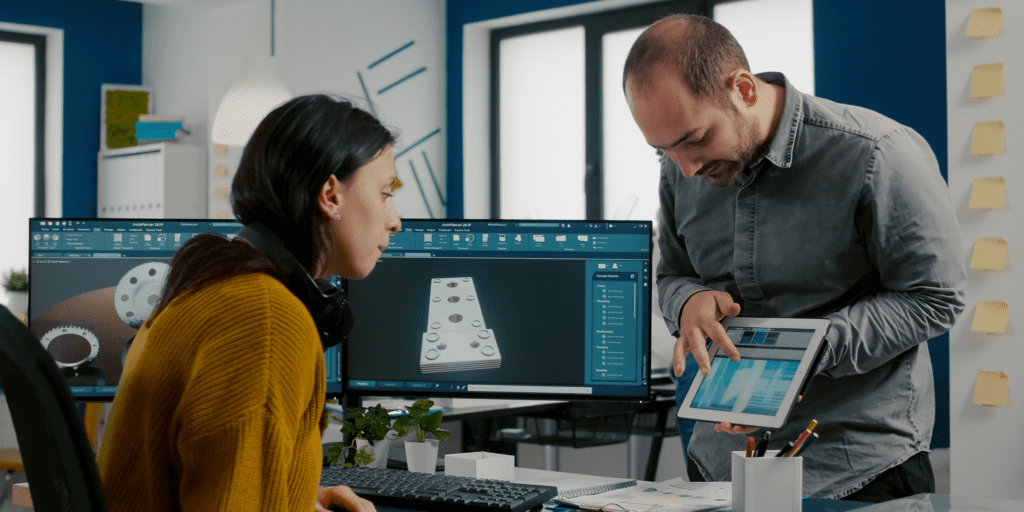

My name is Siobhán Ní Chofaigh and I am the founder and CEO of Mint-Tek. Mint-Tek helps innovators to design and manufacture hardware prototypes. We help our customers with creating design files that are ready for manufacture. For some customers, we project manage their PCB assembly, while others are just at the very beginning of the design process and we guide them through to an early stage manufacturing prototype.

Can you tell us about the customers and their industries?

Predominately, we work with multinational technology companies and OEMs. We are industry agnostic, though most of the design projects are focused on automotive, HVAC, building technology, consumer technologies and agritech. We also provide prototype guidance to some start ups in the IoT space as they bring their ideas to life.

What types of products, innovations and technologies do these companies require your support on?

Mint-Tek has a wide network of hardware and software partners, so we can support our customers incorporate cutting edge technologies into their prototype designs. We find that these projects contain applications using sensors, wireless communication and data outputs. Nowadays, that covers just about everything.

What about ideas coming outside of your industry?

If anybody needs help in the design or build of electronic products, in small to medium volumes, we’re there to help. We work with several companies that started with an idea outside our industry. So people who might have a different market or different expertise, but want to develop a hardware product to put software onto or to test something. In these projects, the customer would get in touch with us because basically, they don’t know where to go from an electronics perspective.

Perhaps they have made a “kitchen table” prototype of their idea using Arduino or Raspberry Pi, but are not familiar with the manufacturing process. Mint-Tek can help them move their design to manufacturing. While they know their market inside and out, they may not have experience with supply chains or manufacturing factories. This is where we come in as we have the network and skillset to help them, a mini factory. As we always say, hardware is hard, but it doesn’t have to be!

An example of this would be when these products are brought to manufacture. You may have estimated a certain time for production, however when it starts being produced the supply chain or testing has not been taken into account. Even an extra 10 minutes on each product for testing could put your project massively over budget. Manufacturing at scale has a lot of manual steps, which always surprises people.

We also consider the materials involved in producing your product. Another example would be if the circuit board in a design is too large for most manufacturers, meaning your pool of assembly houses is smaller. Again this will raise your cost per unit, often resulting in a cost higher than your sale price. We can help them address these supply chain issues ahead of time, saving them time and money. The end consumer sale price is always a consideration for us.

—

To get in touch with the Mint-Tek team contact us here.