Utilizing Advanced CAD Design and 3D Printing for Quality Prototypes: Our commitment to the latest 3D CAD design software and 3D printing technology enables us to craft stunning, precise prototypes efficiently. By embracing these cutting-edge tools, we ensure the production of high-quality, durable parts, meeting our clients’ needs promptly and effectively.

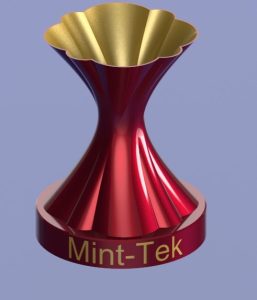

If needed, following the printing process, we meticulously paint and finish the part to meet the customer’s exact specifications. This careful detailing ensures that the completed piece closely resembles a part produced in full-scale manufacturing, achieving a realistic and high-quality appearance.

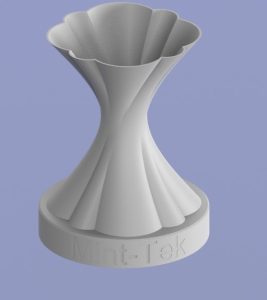

Uncoated 3D printed part

Coated 3D printed part

What is 3D printing

3D printing, technically known as additive manufacturing, involves creating physical objects from a digital file through a layer-by-layer material deposition process. This technique utilizes a digital model, typically designed using Computer-Aided Design (CAD) software. The printer, guided by this model, selectively deposits material, often polymers, resins, or metal alloys, in successive, thin cross-sectional layers. Each layer solidifies upon deposition, gradually building up to form the final three-dimensional object. Unlike traditional subtractive manufacturing, which removes material to shape an object, additive manufacturing adds material only where needed, minimizing waste. This process allows for intricate geometries and complex designs, revolutionizing fields like prototyping, biomedical engineering, and aerospace by enabling rapid, cost-effective, and customized prototypes

Filament printers, commonly known as Fused Deposition Modelling (FDM) printers, are a type of 3D printer that create objects by extruding a thermoplastic filament. The filament is heated to a molten state and then precisely deposited layer by layer to build the desired 3D object.

Resin printers, also known as Stereolithography (SLA) or Digital Light Processing (DLP) printers, are a type of 3D printer that uses light to cure liquid resin into solid objects. These printers work by exposing the liquid resin to a light source (like a laser or projector), which hardens the resin layer by layer to form the final object. Resin printers are known for their high precision and ability to produce very detailed and smooth-surfaced parts.

Mint Tek is building a platform and a network of PCB manufacturing and hardware prototype assembly partners to make this process simple, cost-effective and easy for busy hardware developers.

[

Mint Tek is building a platform and a network of PCB manufacturing and hardware prototype assembly partners to make this process simple, cost-effective and easy for busy hardware developers.

[